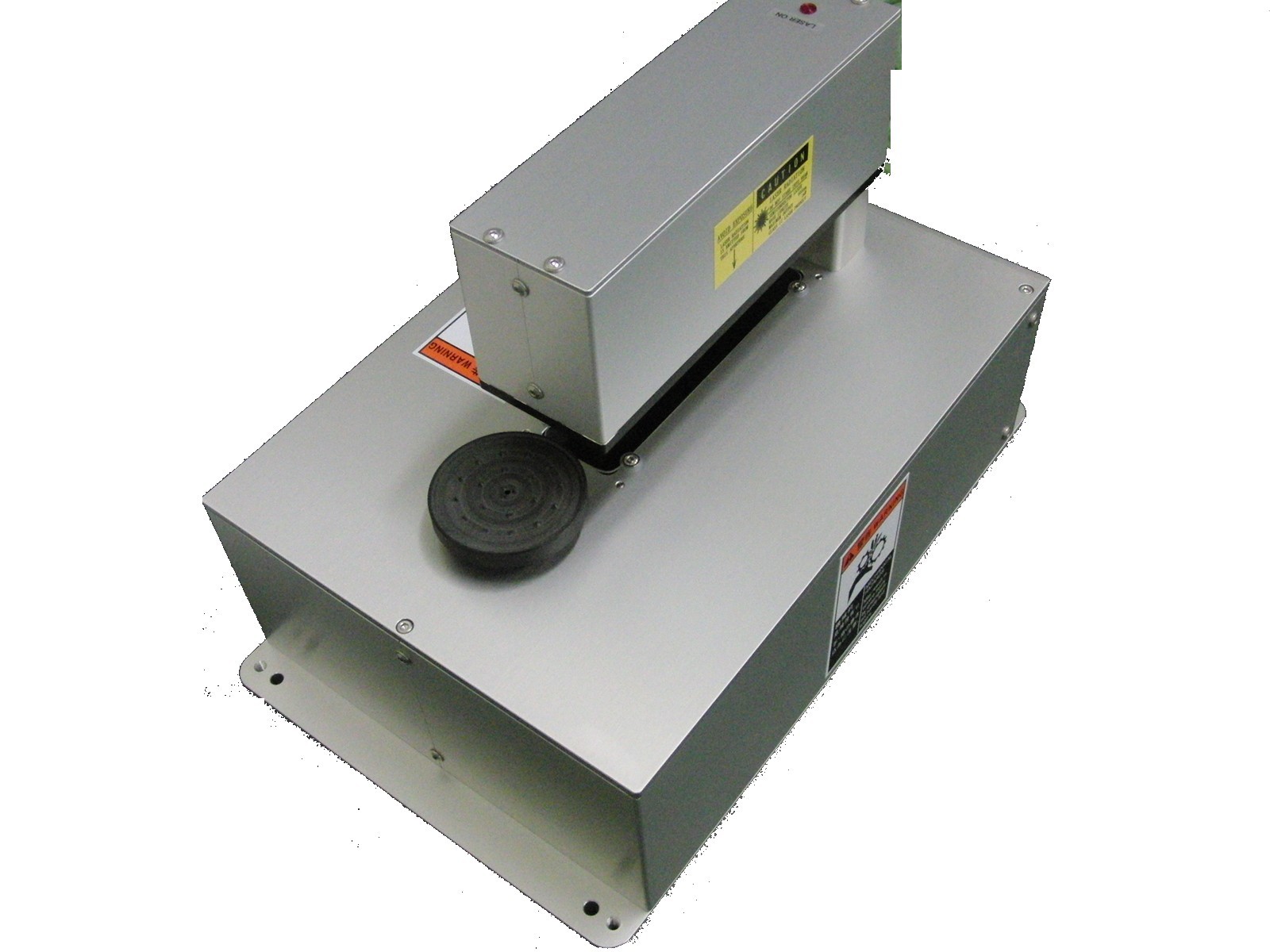

TA300A-VBD

This aligner enables to detect a wafer position by using a built-in sensor and to align a notch or orientation flat.

For centering of VA type, the additional mechanism(Robot etc) to execute a motion correction based on the data output from an aligner will be required.

Features

- Originally developed lader sensor enables to detect it regaedless of materials of wafer.

- The wafer size of 200mm to 300mm are automatically discriminated.

- Compact design realized a built-in controller.

- Guaranteed for three(3) years by high reliability design.

Specifications

| Handling object |

φ200mm to φ300mm SEMI/JEIDA standard wafer. (Please inquire with regard to special wafers such as glass wafers.) |

| Alignment time |

2.5seconds or less |

| Alignment accuracy |

XY:±0.1mm or less(3σ) θ:±0.1° or less(3σ) |

| Wafer off-center limit |

±5mm or less (Wafer offset from chuck center) |

| Wafer holding method | Backside vacuum chuck |

| Wafer hold check | Pressure sensor |

| Communication |

RS-232C(Serial Interface) |

| Utility |

Power:DC24V±10% 2A 1line Vacuum:φ6mm -80kPa or less 15L/min.1line |

| Mass | Main body:Appox.5kg |